As most product developers know, cosmetics manufacturing is largely dependent on mixing. Virtually every product, regardless of formula type, requires the perfect blending of ingredients to achieve the desired appearance, texture, performance and shelf life. Whether developing a creamy lotion, a hydrating lipstick, an anti-aging face mask, a setting powder or a gel serum, getting the right mix at all stages of production is critical.

Log in to view the full article

As most product developers know, cosmetics manufacturing is largely dependent on mixing. Virtually every product, regardless of formula type, requires the perfect blending of ingredients to achieve the desired appearance, texture, performance and shelf life. Whether developing a creamy lotion, a hydrating lipstick, an anti-aging face mask, a setting powder or a gel serum, getting the right mix at all stages of production is critical.

The process of creating a winning formulation in the lab and translating it to a larger scale requires a combination of empirical data, hands-on experience and practical wisdom. This is as true for a thriving startup that has outgrown its R&D “pilot plant” (i.e., kitchen) as it is for a well-established brand gearing up for its largest campaign yet.

Scaling up production, of course, goes beyond increasing ingredient amounts and investing in equipment. The challenge lies in reproducing the physical and chemical properties of the final product on a larger scale while upholding manufacturing efficiency and product quality (for more on this, see Lionetti). This is where specialty mixing equipment can help to support a successful product scale-up and avoid a potentially expensive and time-consuming lesson.

This article outlines critical components in the scale-up of cosmetic products. It describes the dynamics of scaling, mixing and blending equipment considerations, and ways to streamline raw material additions and customize processes to improve production.

Adapting to Scale

The textbook concept of scalability is defined in terms of process, material and machine variables grouped into ratios and equations and establishing geometric, kinematic and dynamic similarities. However, most of these formulas apply only to simple, low-viscosity liquid-liquid mixing systems of similar densities involving a single agitator. In reality, most mixing applications are much more complex and often involve multiple stages that correspond to varying levels of viscosity, density, vacuum/pressure requirements, shear-sensitivity and heat requirements that cannot be neatly quantified using standard scale-up equations. As such, traditional academic analysis provides only a starting point. From there, scaling up relies mostly on experience and the ability to identify and control the most important variables at work in a specific application.

Translating a proven laboratory or pilot process into full production, the goal is essentially to replicate the amount of mixing energy and particular flow pattern to lead to the desired finished product. Realistically, it is not always feasible or practical to maintain power per unit volume but qualitative changes in mixing dynamics can be minimized by ensuring geometric similarity (agitator style, agitator-to-tank diameter ratio, relative position of agitator along tank height, etc.) and maintaining agitator tip speed. The unavoidable decrease in the surface area-to-volume ratio necessitates longer mixing times, especially when the batching process is accompanied by heating or cooling.

Mixing trials using actual raw materials and simulating actual operating conditions are essential for generating reliable data for scale-up. It is generally recommended to perform tests using a mixer that is no smaller than 10% of the capacity for the intended final scale-up amount. This helps to ensure the mixing results will be representative of the larger production environment.

Further, some manufacturers offer testing services that are supervised by mixing experts. Alternatively, many OEMs provide rental equipment for in-house trials. Investing in scale-up testing up front can lead to significant savings in time, cost and resources down the line.

Mixer Considerations

Various types and styles of mixing equipment are used in the cosmetics industry. The appropriate choice is determined by the phases being mixed (i.e., liquid-liquid, solid-liquid or solid-solid), the level of shear or mixing intensity required, as well as physical characteristics of the end product, such as viscosity and density.

Many mixing technologies overlap, and certain applications can be successfully produced by two or more types of mixing systems. In such scenarios, assessing both economic considerations and efficiency becomes pivotal for process optimization. The common denominator when choosing R&D equipment is that it must be truly scalable. Kitchen mixers and blenders, while convenient for small batches, are simply not available in larger production-size models. Following are examples of scalable mixers in which geometric ratios and tip speeds are easily reproduced across the entire product line.

High shear mixers: High shear mixers are ideal for reducing the size of agglomerates and droplets in fine dispersions and emulsions to create scalable, highly repeatable products. These mixers consist of a single stage four-blade rotor that turns at high speed within a stationary stator (see Figure 1). As the rotating blades pass each opening in the stator, they mechanically shear particles and droplets and expel material at high velocity into the surrounding mix, creating intense hydraulic shear. As fast as material is expelled, more is drawn into the bottom of the rotor/stator generator, which promotes continuous flow and fast mixing.

Figure 1. High shear mixerCharles Ross & Son Co.

Figure 1. High shear mixerCharles Ross & Son Co.

High shear mixers come in batch and inline designs that can process volumes as small as one liter or as large as several thousand gallons at a time. Depending on the rotor/stator geometry, a high shear mixer can handle applications up to 10,000-20,000 centipoise (cP), such as lotions, creams, serums, balms, liquid foundation, masks, nail polish, hair colors, shampoos, conditioners, fragrances and many others.

Multi-shaft mixers: Multi-shaft mixers consist of two or three independently driven agitators that work in tandem, making them highly versatile. In a typical configuration, the critical role of powder wet-out and dispersion is carried out by a high-speed sawtooth disperser. The rotor/stator, another common component of multi-shaft mixers, homogenizes the product by further breaking down solid agglomerates and/or emulsifying immiscible phases.

A low-speed anchor agitator promotes bulk flow and uniform composition. It is capable of scraping the vessel sidewalls and bottom for optimal heat transfer across the jacketed surfaces. Multi-shaft lab mixers are suitable for a wide range of applications, from thin slurries and solutions to viscous pastes and suspensions.

Aside from the improved capability of multi-shaft mixers over single-shaft devices from a viscosity and heat transfer standpoint, another design advantage is they are closed systems and offer benefits in vacuum mixing. When processed under vacuum, certain cosmetic formulations such as slurry powders may develop deeper color and, after baking or drying, can develop better pay off and other properties due to improved shearing and dispersion of the different components. Also, vacuum mixing keeps entrapped oxygen to a minimum, which improves the shelf life and stability of products.

Planetary mixers: For very high viscosity formulations (> 500,000 cP), planetary style mixers are much more effective at thoroughly combining raw materials and ensuring compositional uniformity. Employing two identical blades that rotate on their own axes while orbiting on a common axis, double planetary mixers easily handle tacky semi-solids and dough-like consistencies. The blades continuously advance along the periphery of the vessel, removing material from the vessel wall and transporting it to the interior.

Planetary dispersers are hybrid systems consisting of a disperser and a planetary stirrer (or two of each) – a very robust arrangement designed for mixtures that start out very fluid-like and thicken significantly throughout the course of the batching process. They are sometimes used for dry powder blends as well.

Ribbon blenders: In the world of cosmetics, various dry blending applications are common. Ribbon blenders are often the practical choice for straightforward free-flowing powders, beads, granules and other solids. These feature a U-shaped horizontal trough and an agitator composed of inner and outer helical ribbons that are pitched to move material axially in opposite directions, as well as radially. Ribbon blenders are simple mixing agitators – single rotating blades with no internal parts, so they are relatively easy to clean and maintain, even when subjected to frequent changeovers.

Tumble blenders: Tumble blenders are characterized by a vessel in a double cone or V-shaped configuration that rotates on a horizontal axis. Generally, the vessel turns at a speed of 5 to 25 revolutions per minute. Diffusion is the main mechanism for mixing: batch materials cascade down, distributing particles over a freshly exposed surface as the vessel rotates on a horizontal axis.

Tumble blending has a very low impact and is appropriate for processing friable ingredients. It is also commonly used to make precise blends containing trace ingredients or additives. Proper blending is essential to producing physically homogeneous powders within a target particle size distribution that have excellent flow properties. One main advantage of the double cone and V cone vessel is that their geometry allows for the complete discharge of the blended material.

Streamlining Raw Material Additions

Adding difficult-to-disperse powders slowly into a small batch of vigorously agitated liquid is generally not an issue in lab-scale batches. However, in a full-scale production setting, this method of addition can be costly and time consuming.

For example, batch mixing can be used to serve various objectives, such as dispersion, particle size reduction and solubility. However, difficult-to-disperse powders pose challenges to conventional methods. Such powders, including carbomers, xanthan gum, maltodextrin, guar gum and carrageenan, can form agglomerates known as fish eyes, if added too quickly to the liquid phase. Furthermore, the high-shear conditions usually required to break up these agglomerates may over-shear the already-hydrated or dispersed particles, leading to a permanent loss in viscosity.

In turn, to correct below-target viscosities, many manufacturers resort to adding more solids than are needed, subsequently filtering agglomerates out of the mixture. This not only drives up raw material costs, but also wastes power, lowers productivity and constrains overall production.

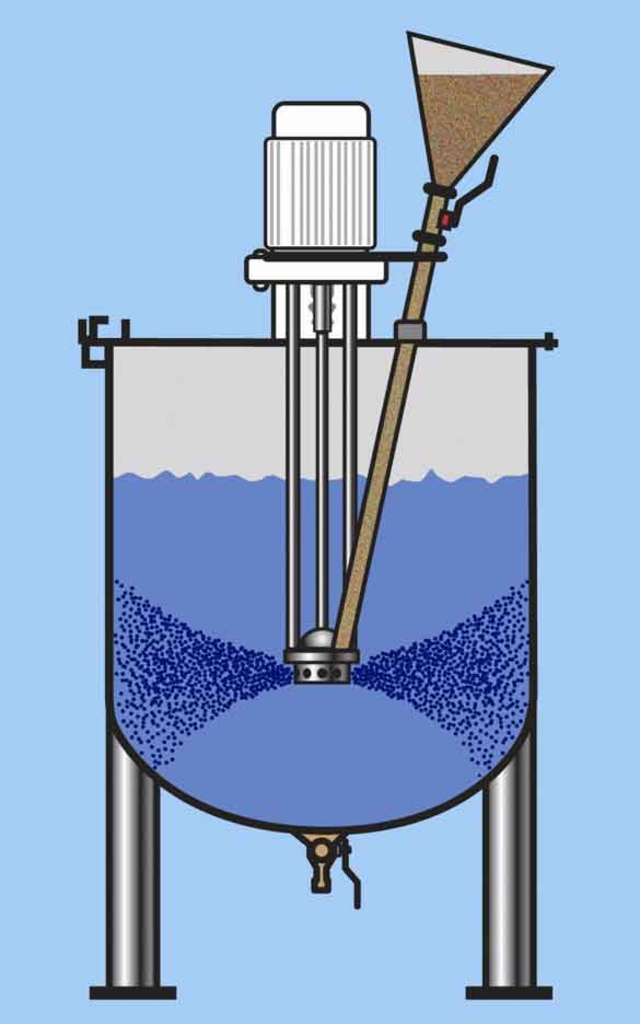

For large batches that require mixing solids into a liquid, an inline powder injection system can be a beneficial tool. In this case, the rotor/statora works with high shear and multi-shaft mixers to generate an intense vacuum in the high shear zone and suck powders into a fluid stream (inline) or sub-surface (batch) (see Figure 2). Combining solids and liquids at the exact point where intense mixing takes place provides immediate, high-quality dispersion.

Figure 1. Inline powder injection system, the rotor/stator works with high shear and multi-shaft mixers to generate an intense vacuum in the high shear zone and suck powders into a fluid stream (inline) or sub-surface (batch).Charles Ross & Son Co.

Figure 1. Inline powder injection system, the rotor/stator works with high shear and multi-shaft mixers to generate an intense vacuum in the high shear zone and suck powders into a fluid stream (inline) or sub-surface (batch).Charles Ross & Son Co.

Customizations to Improve Production

Once the correct mixer is chosen, several customizations can be made to greatly improve production efficiency. These options can serve as catalysts for improved efficiency, product quality and overall operational excellence, positioning businesses to meet the dynamic challenges of modern manufacturing.

Simplified sanitation: Companies should discuss with their mixer manufacturer what options are available to make cleaning easy and uncomplicated. Examples include high polish on stainless steel surfaces, sanitary fittings and valves that can be quickly disassembled, easy access to agitators, drain port and clean-in-place (CIP) spray nozzles for efficient wash down.

Change-can mixer designs: Scaling up to a larger mixer with a "change-can" design can significantly enhance production efficiency. This enables semi-continuous processing, where a single mixer is supplied with multiple interchangeable vessels. The vessels cycle through a sequence of charging, mixing, discharging and cleaning. This approach streamlines the production process by minimizing downtime between batches. It also allows for more consistent and efficient production, especially in scenarios where different formulations need to be produced consecutively.

Efficient control systems: The mixer's control system plays a vital role in optimizing energy usage, serving as a critical link between operator and machine. A well-designed control system contributes to consistent product quality and shorter changeover times and minimizes the potential for operator errors.

The choice between simple or advanced process controls depends on the unique demands of each operation. At minimum, the integration of a variable frequency drive (VFD) offers notable advantages. A VFD enables a soft start, reducing electrical demand by gradually accelerating the motor and thereby minimizing current surges during startup. When applications require variable mixer speeds to optimize flow patterns, shear levels or throughput, a straightforward VFD-controlled electronic speed system proves to be a cost-effective solution.

For more complex operations, programmable logic controller (PLC) control alternatives are a strategic choice. These advanced systems seamlessly integrate data such as agitator speeds, mixing duration, temperature, batch weight, vacuum/pressure levels and other variables into recipes. They also maintain automatic records for each run, providing a comprehensive view of the process and allowing operators to monitor and control the human machine interface (HMI) screen from a smart phone or tablet (see Figure 3). These systems can be configured to automatically send text or e-mail messages regarding operating status, production concerns or alarm notifications.

Figure 3. Programmable logic controller

Figure 3. Programmable logic controller

Charles Ross & Son Co.

Whenever possible, it is advisable to source control solutions from the mixing equipment provider. This ensures smooth project execution, covering design, production, installation and commencement. Opting for controls integration alongside mixer procurement guarantees that the equipment is ready for use upon setup, expediting enhanced production efficiency.

Partnering with Experienced Suppliers

Finally, even with a well-defined plan and the best quality equipment, there may be challenges and obstacles that require adjustments to optimize the production process at a larger scale. This is where partnerships with experienced suppliers and original equipment manufacturers (OEM) are invaluable, as these companies have a wealth of knowledge and expertise in specialty mixing.

Experienced OEMs have encountered a wide range of scenarios and challenges and their insights can help to navigate the scale-up process more smoothly. So, whether fine tuning equipment, addressing unexpected issues or using OEMs’ testing and development centers, guidance from these companies can make a significant difference in the success of the scale-up process.

a ROSS Solids/Liquid Injection Manifold (SLIM)